Sheet Metal Design - Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. Features into a flat sheet. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas.

To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. Features into a flat sheet. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs.

Features into a flat sheet. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs.

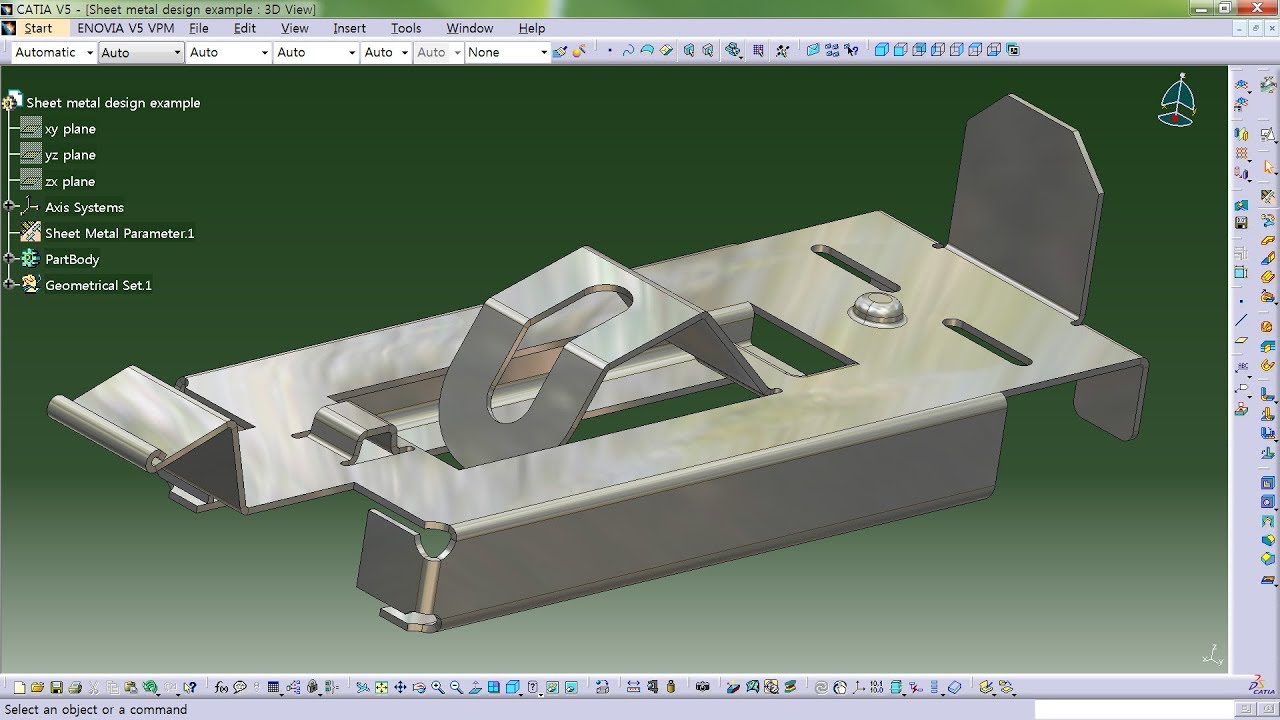

Sheet Metal Design Considerations at Freda Robert blog

Features into a flat sheet. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5.

sheet metal gusset design guidelines Captions Time

Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. Features into a flat sheet. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5.

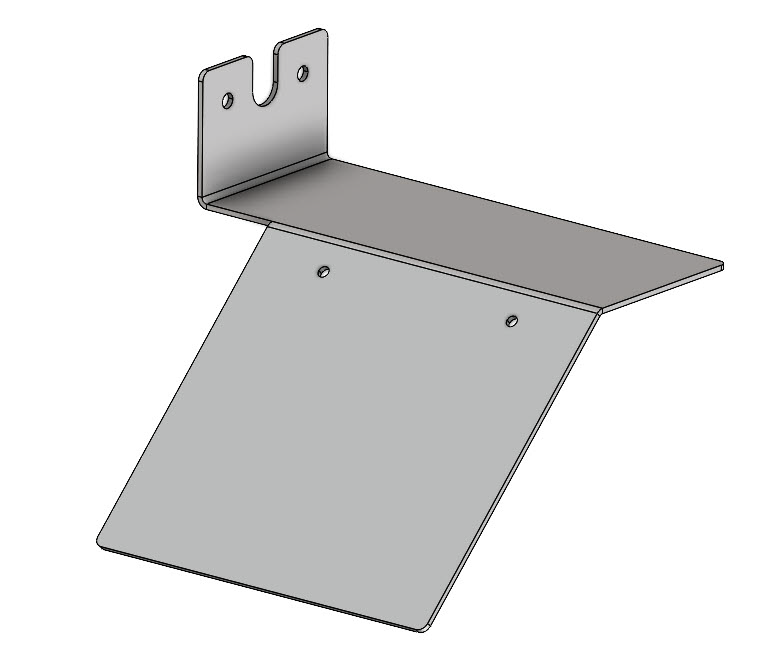

Sheet Metal Design Ideas Onshape Goes Metal. Sheet Metal. Bodaqwasuaq

Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. Sheet.

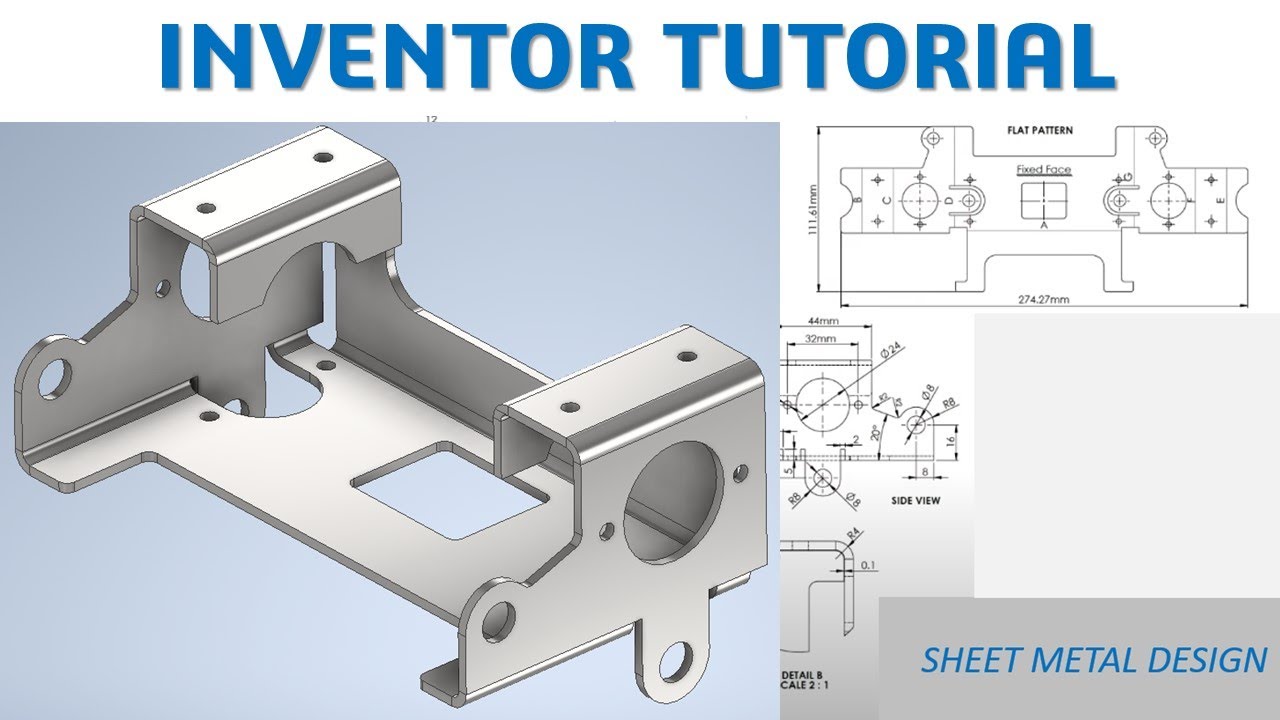

Inventor 2022 Tutorial 230 3D Sheet Metal Design YouTube

Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Features.

Sheet Metal Design Guide for Product Manufacturing cncfirst

To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. Features.

Cool Sheet Metal Designs

To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and.

Laser Cut Steel Panels

Features into a flat sheet. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5.

Sheet Metal Design Engineer Jobs at Charlotte Sanchez blog

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production.

Sheet Metal Design Ideas Onshape Goes Metal. Sheet Metal. Bodaqwasuaq

Features into a flat sheet. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design formulas. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe.

Cool Sheet Metal Designs

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs. To help you achieve the highest standard of fit and function for your parts, we're sharing the top 5 sheet metal design.

To Help You Achieve The Highest Standard Of Fit And Function For Your Parts, We're Sharing The Top 5 Sheet Metal Design Formulas.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Features into a flat sheet. Geomiq's sheet metal design guide helps you with your design process to accelerate production time and reduce production costs. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering,.